I. SUMMARY INFORMATION

Project

269868

Status

Submitted

Award category

Solutions for the co-evolution of built environment and nature

You want to submit

NEW EUROPEAN BAUHAUS RISING STARS : concepts or ideas submitted by young talents (aged 30 or less)

Project title

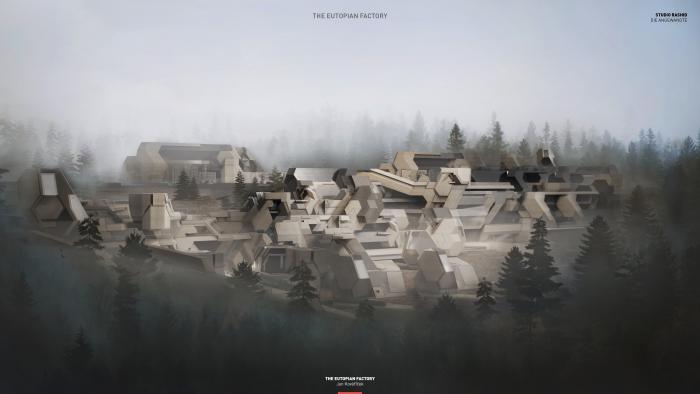

The Eutopian Factory

Full concept/idea title

The Eutopian Factory: An alternative to the Industrial Exploitation

Description

The Eutopian Factory outlines an alternative to the current model of industrial manufacturing. Leaving behind excessive production and environmental exploitation of the last 150 years, it embraces key concepts of pre-industrial labour (such as highly skilled workforce, sustainable scale of resource harvesting based on local availability, clustering into self-sufficient production hamlets, avoiding overscaling the production rate) and updated with the current possibilities of Industry 4.0.

Where is your concept/idea being developed or intended to be implemented in the EU?

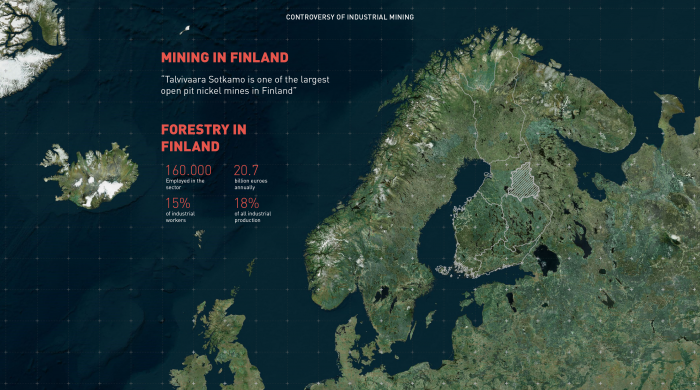

Finland

Kainuu region

Sotkamo

Sotkamo

88120

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your concept/ idea

The Eutopian Factory (from Greek eutopia – meaning: "a good place", rather than outopia – meaning: "non–existent place") outlines an alternative to the current model of the industrial manufacturing. Leaving behind an excessive production and environmental exploitation of the last 150 years, it embraces key concepts of the pre-industrial labour (eg. value generated by highly skilled workforce, sustainable scale of resource harvesting based on the locality, clustering of production in self-sufficient manufacturing hamlets) and is updated with the current possibilities of Industry 4.0 (understanding the automation as an enabler of mass customisation, focus on positive externalities) in regards to the phenomenon of digital craftsmanship.

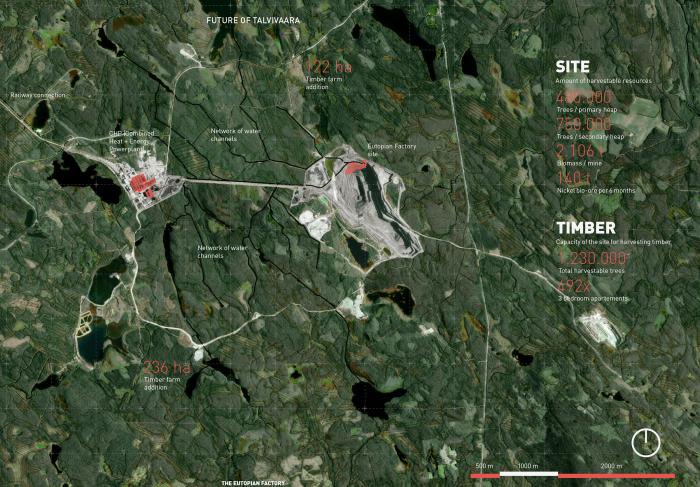

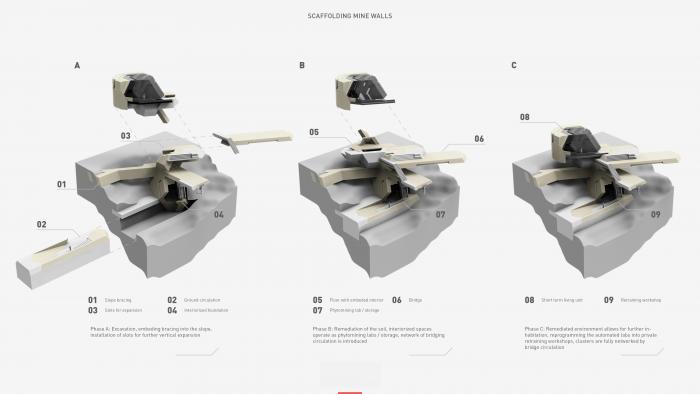

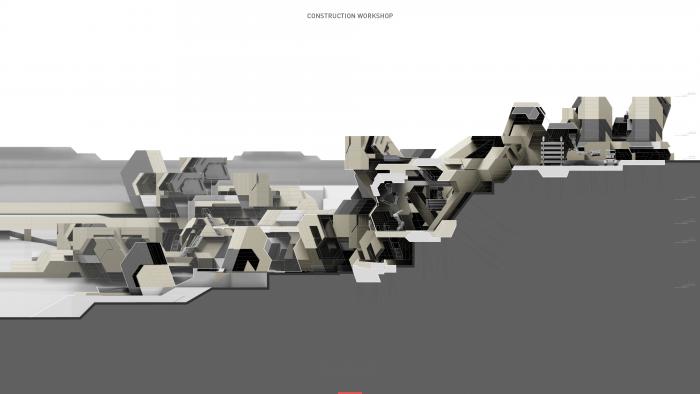

Through a development of a long term strategy for both ecological and societal scenarios project framework investigates a future of sustainable timber production, in which the machine is co–performing with a human in a production of digitally crafted system of interlocking discrete building elements made out of localy produced CLT (cross-laminated timber). Proposed system enables mass–customisation over mass–production while reversing industrial footprint in the area of highly polluted nickel mine in Europe, the Talvivaara mine (Kainuu region, Finland). This is done so by devising a remediation strategy that introduces a sustainable co-shared forestry model and usage of nickel accumulating („hyperaccumulating plant species“) plants for cleaner nickel extraction and remediation of the devastated land.

Outcome is a synthesis between methods of sustainable harvesting and maintenance of the natural habitat with an architectural program focusing on a man—machine collaboration which aims at (re)training blue collar workers in using digital fabrication tools. Current fears in regards of the automation’s effect on the labour market are thus offset in perspective of new collaborative opportunities.

Please give information about the key objectives of your concept/idea in terms of sustainability and how these would be met

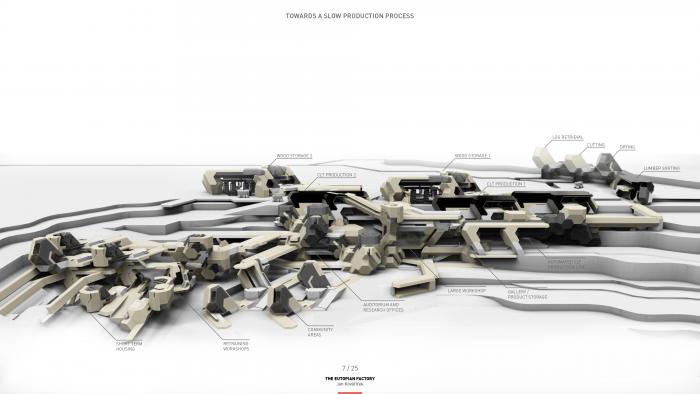

Rethinking the fabrication process of cross–laminated timber (CLT) for building construction

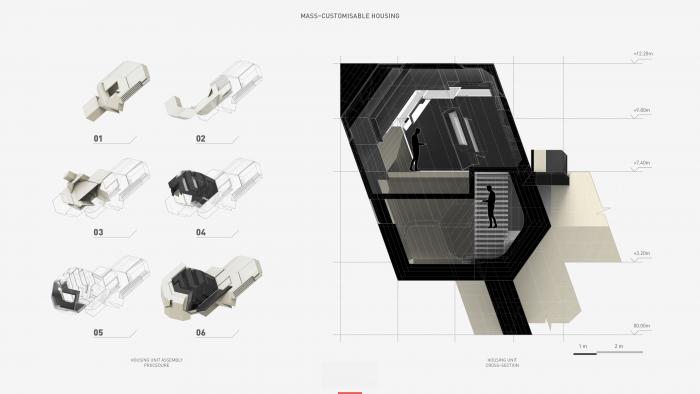

Project proposes full integration of a robotic assembly line based on the examples from contemporary automotive facilities (1). Currently, the CLT (2) fabrication relies heavily on a 2.5D processing space (3). By using high precision robotic manipulators operating in 3D space a complex prefabricated construction can be achieved. This degree of manipulation allows for an interlocking assembly of loadbearing mass timber elements in combination with light, rib-like hollow parts which embed MEP based on the custom specifications.

Eg. upcoming Tesla Gigafactory Berlin–Brandenburg, Germany

CLT – Cross–Laminated Timber — Wood based construction material with isotropic properties – unlike mass timber its properties are the same in both directions. Developed in 1990's in Germany and Austria the material is praised for its low carbon footprint, as an efficient carbon sequester and for its mechanical properties equal to concrete.

So far the CLT production line mostly uses more traditional, plotter-like formatting machines - machines that are efficient in processing large, continuous sheets of planar material, but are unable to process three dimensional pieces.

Please give information about the key objectives of your concept/idea in terms of aesthetics and quality of experience beyond functionality and how these would be met

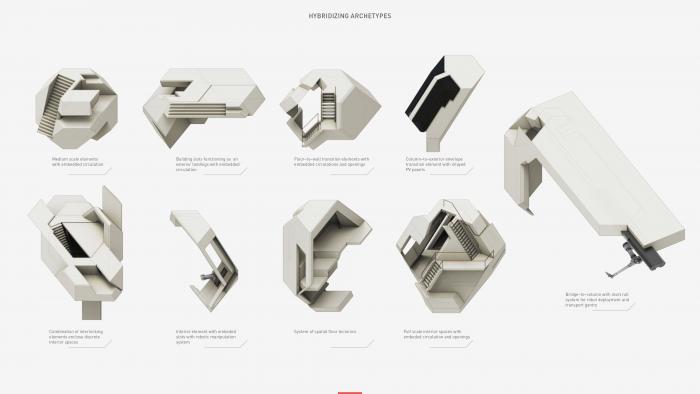

From mass–produced to mass–customised — proposing a system of interlocking discrete modules of an architectural scale

The tectonics are based on an interlocking logic applied to a set of discrete architectural elements. It is based on details of classical carpentry joining systems and interlocking assembly of traditional japanese wood joinery techniques. These two systems are supersized into architectural scale of building elements. By following same ruleset of interlocking logic, a production of non-standardized yet tectonically compatible artisanal building elements is achieved. These custom pieces question the traditional understanding of construction archetypes (1) experimenting with hybridization of functions (2).

Traditional construction archetypes of modernism based on Le Corbusier’s Maison Dom(Ino): wall, column, ceiling, staircase all as distinct tectonic entities

Embedding human and machine circulation, inlaying facade PV panels, etc.

Please give information about the key objectives of your concept/idea in terms of inclusion and how these would be been met

Apart from the long term remediation strategy of the devastated nickel mine, project's agenda aims at introducing automated tools into the new era of "digital craftsmanship". Its goal is to offer a retraining facilities with short term living units for European citizens inclusive of nation, age, gender or religion that might feel endangered by wide spreading automation and digitisation into their sectors of work (ie. group of European citizens that would identify themselves as "blue collar workers"). By offering state of the art retraining tools and environment based on the idea of pre-industrial manufacturing hamlets, workers can train and gain knowledge in small scale production on cosmolocal (1) scale. The framework is inspired by existing network of "FabLabs" but enhancing it with aspects of sustainable community living to encourage sensitive co–living with our natural habitat.

Cosmolocal movement — "think and share knowledge globally, produce locally"

Please explain the innovative character of your concept/ idea

Through a strategy for both ecological and societal scenarios this project investigates a future of sustainable timber production in which machine is performing most of the mechanically demanding actions. Due to the current implementation of digitisation processes (1) in the timber production industry the material production can smartly adapt to the current demand without exploiting locally available volumes. Focusing on problematic of ore extraction, project speculates on using a remediation strategy which includes sustainable co-shared forestry model and utilization of hyperaccumulating plants for ore extraction with a longterm goal of remediating the devastated land. The outlined strategy consist of 5 phases: Remediation (2), Production (3), Processing (4), Fabrication (5) and RnD (6). The miners that previously operated the mine retrain within the newly built facility to become digital craftsmen.

The automated processes control the quality of lumber and can customise production output, abandoning constant material production

Phytomining reverses pollution of pit mining by extracting nickel from soil via plant roots, instead of invasive technique that destabilizes mine slope and pollutes the environment

As a part of industry paradigm shift new system of sustainable timber farming is established. Hyperaccumulators are burnt at the combined heat and energy power plant (CHP). The CHP provides district energy and seasonal heat for the region. The burnt residue is rich in nickel and is exported as viable source of nickel

Using tools for digital forestry and automation to create effective, holistic resource management and production

Together with remediation strategy the factory’s main goal is to test and develop novel architectural and tectonic language of CLT mass timber constructions.

Production of the mass–customised construction elements serve as didactic tool for retraining dwellers in becoming digital craftsmen embracing automation and Industry 4.0

Please detail the plans you have for the further development, promotion and/or implementation of your concept/idea, with a particular attention to the initiatives to be taken before May 2022

Past: Project was selected and presented on global architectural platform "DigitalFutures Young" initiative. Core ideas of project were introduced to the students in several European universities of art, design and architecture as a part of authors academic and educational activities in the field of architecture and digital fabrication.

Future:

Continuing the independent research on the phenomenon of digital craftsmanship and sustainable small scale production with focus on well–being of our environment. Further design research into new materiality for building construction in regards of the above mentioned.

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed concept/idea has not been proposed for the New European Bauhaus Rising Stars Awards more than once in the same category.

Yes