I. SUMMARY INFORMATION

Project

268126

Status

Submitted

Award category

Techniques, materials and processes for construction and design

You want to submit

NEW EUROPEAN BAUHAUS AWARDS : existing completed examples

Project title

BUGA Wood Pavilion

Full project title

Innovative, Lightweight, Sustainable and Fully Reuseable Segmented Wood Shell Structure

Description

The BUGA Wood Pavilion celebrates a new approach to digital timber construction. The stunning wooden roof spans 30 meters over a public event area, using a minimum amount of material while also generating a unique architectural space. The pavilion was developed by a interdisciplinary team of architects, engineers, scientists, craft and public stakeholders. Due to its innovative building system it can be fully reassembled at a new location and completely recycled at the structures end-of-life.

Where was your project implemented in the EU?

Germany

Baden Württemberg

Kalistraße

49°08′53.2″N

9°12′25.3″E

Heilbronn

74076

When was your project implemented?

Has your project benefited from EU programmes or funds?

Yes

Which programme(s) or fund(s)? Provide the name of the programme(s)/fund(s), the strand/action line as relevant and the year.

The project was partially supported by the EFRE Fund of the European Union and the State of Baden Württemberg under the "Holz Innovativ Programm" 2014-2020.

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your project

The BUGA Wood Pavilion 2019 celebrates a new approach to digital timber construction. It showcases novel sustainable potentials that arise at the intersection of form-active timber structures, robotic fabrication and computational design. Even though wood is the only major building material with a negative carbon footprint – material efficient construction is still highly relevant to mitigate material costs and avoid overuse of sustainably managed forests. Through the pavilions complex form and differentiated structure only a minimum of material is necessary to span 30m across the central event stage at the Federal Horticultural Show in Heilbronn. The pavilion project tied together academics, industry and local craftsmen through an innovative co-design approach. It was visited by more than 2 million visitors during the summer of 2019 and will be fully disassembled and reused in 2023 in the city of Mannheim.

The project was developed by a interdisciplinary and international project team from the ICD/ITKE University of Stuttgart, BUGA Heilbronn GmbH, BEC Robotics, and Müller Blaustein Timber Construction.

Please give information about the key objectives of your project in terms of sustainability and how these have been met

Fully reusable and recyclable Structure for increasingly dynamic societies

The BUGA Wood Pavilion serves as a flexible and high quality event space for the local society. Its warm and inviting interior and very good acoustics create an environment that supports the local community by acting as a stimulus for cultural rediscovery, political discourse and integrative societal understanding. In order to maximize the utilization of the shell as cultural vehicle along its full life cycle, a special design focus was set on the extended utilisation and the reusability of the structure. Through a novel connection detail, the full pavilion can be disassembled and re-erected at a new site, while reusing all layers of the shell structure.

Sustainable and efficient use of wood in construction for performative structures

Timber is the only mayor construction material that can be naturally grown. As such it may be sustainably used to construct the enormous building volume necessary to house a growing global population. Nevertheless, wood is a sought after and rather expensive resource and needs to be used efficiently in order to use its full potential. Following the biomimetic principle of “more form with less material" the BUGA Wood Pavilion showcases a highly differentiated structural system that is only possible to achieve with novel computational design methods and robotic fabrication processes. With a resulting material usage of only 37kg/m2 shell surface area at 30m span the pavilion is demonstrating new performance domains in lightweight and resource-efficient timber construction.

Please give information about the key objectives of your project in terms of aesthetics and quality of experience beyond functionality and how these have been met

Co-Design of an exceptional Public Space

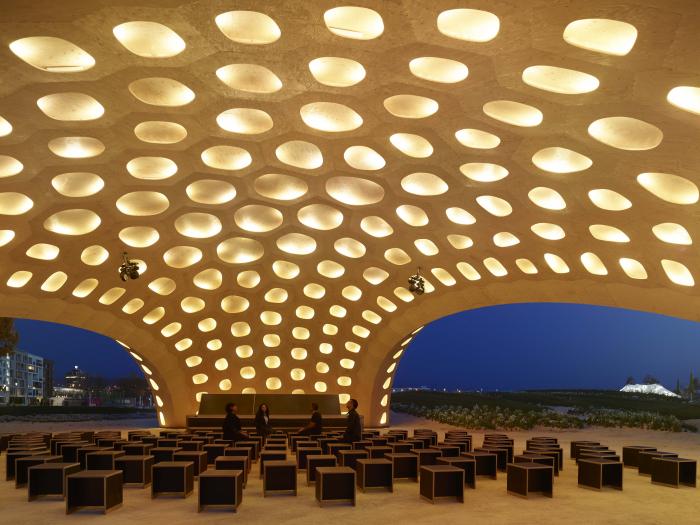

The BUGA Wood Pavilion is located at a central crossroad within the wavy landscape of the BUGA summer island. Three dynamic arches form inviting openings in the main directions and guide visitors into the pavilion’s interior. Hosting concerts and public events, the shell creates a smoothly-curved space that provides exceptional acoustics and generates a unique architectural atmosphere. This is especially true at night, when thousands of LED lights embedded in the shells inner openings light up and bathe the pavilion’s interior in subtle, warm and welcoming light. During the months from April to October 2019 more than 2 million visitors from all over germany and its neighbour countries were visiting the BUGA - with the project's segmented wood shell structure as one of the main attractions. The pavilion's space provided a special environment for a multitude of events: from theater, music and religious celebrations to communal meetings and exhibitions - it's schedule was tightly packed.

The pavilion builds on the biomimetic principle of using “less material” by having “more form”, both on the level of the overall shell and its individual segments. In order to minimize material consumption and weight, each wood segment is built up from two thin plates that plank a ring of edge-beams on top and bottom, forming large scale hollow wooden cases with polygonal forms. The bottom plate includes a large opening, which constitutes a distinctive architectural feature and provides access to the hidden connections during assembly. The lightweight building elements are connected by finger joints, which follow the morphological principles of anatomic features found on the edge of sea urchins’ plates. In the assembled state, the shell works as a form-active structure through its expressive doubly-curved geometry.

Please give information about the key objectives of your project in terms of inclusion and how these have been met

Sustainable integration of digital production into the building culture of traditional craft

The project investigates how automated fabrication technologies can be sustainably included into grown production networks of traditional craft. With the vision of digitally augmenting rather than replacing traditional labour, the production processes of the BUGA Wood Pavilion exemplify the potentials that lie at the intersection of cultural heritage and cutting edge technologies. Only through the combination of human dexterity and machinic accuracy, strength and robustness is it possible to achieve such a highly differentiated and performative structural system at an affordable price.

A distributed robotic platform that plugs into existing local production environments was developed specifically for this project. It aids the productivity of the trade, minimizes transportation and stimulates enthusiasm for the craft in young workers. This follows the philosophy of including construction companies in the process of digital transformation. Rather than betting on disruptive organizational concepts for technological advances, the project exemplifies how automation can be flexibly integrated within local and small to medium sized companies. Therefore it proposes a starting point of an inclusive journey towards safer and more productive construction work through collaboration between the robot and the human.

The project exemplifies how the attentive integration of automation technologies can make the paradigm of building in higher quality with less materials available globally. This is a radical reinterpretion of technology in construction - as usually the embedding of automation technologies is resulting in cuts in building qualities.

Please give information on the results/impacts achieved by your project in relation to the category you apply for

Affordable Material Performance through Automation and Computation

It is not a secret that geometrically more complex building structures can vastly outperform simpler building elements that typically are much easier and cheaper to fabricate. With a rising awareness of the limited nature of our material resources, building systems that leverage such geometric complexity for additional structural performance and material efficiency will be of great importance. The BUGA Wood Pavilion showcases such an approach and offers new technologies to the industry to actually design and build more material efficient without increased fabrication cost by employing computation and robotic fabrication technologies.

Designed for Rapid Reassembly and Reuse

The BUGA Wood Pavilion was designed and built with the spirit of circularity from the very beginning. The segmented shell can be rapidly assembled like a three-dimensional puzzle within only 10 days. This makes possible an affordable relocation of the structure based on societal dynamics. The pavilion was specifically built for the BUGA garden show in Heilbronn in the year 2019 - but will be fully reused at the BUGA 2023 in Mannheim. Rather than redesigning and demolishing, the structure will be simply disassembled and reassembled on the new site.

Full Recyclability at End-of-Life

Even though the BUGA Wood Pavilion can be reused and reassembled multiple times, the materiality of the structure was also carefully designed towards an eventual end-of-life scenario of the structure: the main structural elements of spruce LVL as well as the larch three-ply facade panels can be used to potentially regenerate more energy through thermal energy reclamation than was used from felling the tree to disassembling the shell. The Purenit battens can be fully recycled - as can the pure EPDM water barrier. Steel bolts can be reused or recycled as well - leaving the foundation of the pavilion the only part that can not be reclaime

Please explain the way citizens benefiting from or affected by the project and civil society have been involved in the project and what has been the impact of this involvement on the project

The project team is developing segmented timber shell systems since the year 2011. Throughout the years, the team was actively communicating the progress of the line of research through public presentations, publications and conversations. Especially the design of the direct predecessor of the BUGA Wood Pavilion: the Landesgartenschau Exhibition Hall invigorated fantastic feedback of public, research and architectural design communities. This dynamic public energy was honed for the development of the even more ambitious BUGA Wood pavilion.

In an effort of co-design the BUGA Wood Pavilion was developed from the start together with the public representatives, local carpenters and robotic integrators. This enabled the early embedding of all core qualities into the project that were seen crucial for the success of the project. At completion the BUGA Wood Pavilion received unequivocally positive media coverage and immediately drew hundreds of visitors into its exceptional interior space on a daily basis.

Please highlight the innovative character of the project

The BUGA Wood pavilion was conceived under the paradigm of Co-Design, where novel possibilities in design, engineering and fabrication are explored through continuous computational feedback within an interdisciplinary team. In this project, the co-design algorithms developed by the project team generate the shape of each element of the pavilion according to architectural design intent and structural requirements, while all robotic fabrication aspects are directly embedded and negotiated. The design of the pavilion happens concurrently and in feedback with the design of the robotic manufacturing set-up, which is a bespoke development for the project. The highly integrative process enables the design and engineering of 376 unique plate segments with 17 000 different finger joints in response to multifaceted design criteria, from the scale of the overall structure down to sub-millimetre details. Without any loss of precision, this multi-scale approach allows addressing architectural and structural considerations concurrently. Despite the pioneering character of the project, and despite an incredible short development time of only 13 months from commission to the opening, the integrative computational process allows for the careful design of each building element in minute detail.

Please explain how the project led to results or learnings which could be transferred to other interested parties

The BUGA Wood Pavilion serves both as a demonstrator of novel technologies and a case study in new ways of designing and manufacturing. As it was developed within the context of research, the project resulted in numerous publications, presentations and conversations that depict the lessons learnt.

The main take-aways of the project include a deeper insight into the integrative potential of the cassette building system to serve both as highly performative structural system as well as a unique architectural space with exceptional acoustic conditions. Further new methods of rapid computational design organizations were developed, demonstrated and documented that can be transferred directly to other building types. The robotic platform used in the project, can be flexibly integrated into upcoming projects at any location and with new potential partners.

Is an evaluation report or any relevant independent evaluation source available?

No

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed project has not been proposed for the Awards more than once under the same category and that it has not been subject to any type of investigation, which could lead to a financial correction because of irregularities or fraud.

Yes