I. SUMMARY INFORMATION

Project

269388

Status

Submitted

Award category

Techniques, materials and processes for construction and design

You want to submit

NEW EUROPEAN BAUHAUS RISING STARS : concepts or ideas submitted by young talents (aged 30 or less)

Project title

SUPERLOCAL

Full concept/idea title

SUPERLOCAL, 0 miles production

Description

SUPERLOCAL 0 miles production is a global network questioning and exploring the possibility of producing everyday-life objects locally.

Where is your concept/idea being developed or intended to be implemented in the EU?

Italy

Piemonte

Via Garibaldi 31

Torino

10122

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your concept/ idea

SUPERLOCAL 0 miles production is a global network questioning and exploring the possibility of producing everyday-life objects locally. We envision a world where machines are taking care of repetitive mass-production, while the humans are dedicated to non-alienated uplifting labour. Therefore, by enjoying the great digital and analogical tools that are available, we make the objects we need. Diving into every town living networks of peoples, materials and processes we connect and prototype new local supply chains for daily life objects. In fact, in order to play the contrast between the global and the district scale, we organise a constellation of activities around each new production. Therefore, we organise production tours, workshops and classes in collaboration with the local production actors. Such events are addressing whoever wants to know more about how objects are made and actually experience their making process. The objects become portals to many kinds of knowledge, from places to craftsmen, from materials to processes. The potential of SUPERLOCAL is to expand the local economy and raise awareness within the local communities of what is on their doorstep. After having tested such concept in more than eight different towns in Europe we can count on the experience of sixteen different new local supply chains, three production tours and more than fifteen workshops and conferences. You can visit the project at: www.super-local.org

Please give information about the key objectives of your concept/idea in terms of sustainability and how these would be met

SUPERLOCAL, 0 miles production fosters a future vision on crafts and more in general on production. It wants to open up a production perspective which is an alternative to the more common mass-produced ones. The value of the project lies in being an alternative as we believe that designers nowadays should encourage a process of broaden the spectrum of what is imaginable. Starting from the fablab network, the project elaborates a further layer, embracing also traditional manufacturing techniques. It is through the mix between new and old manufacturing techniques that every object is made. Doing so, we want to avoid crafts nostalgia on one side, and digital proudness on the other. Making things locally, being also aware that that wouldn’t be possible for all the objects we use daily, is sustainable as we avoid shipping on one hand and build stronger local ties on the other. These ties work on two levels: firstly between the user and the producers, and secondarily between the producers themselves, which sometimes never had the chance of collaborating with their colleagues that are based just few streets away. Let me also add that during the last year of pandemics we experience even more the need of connecting with our district and local activities. SUPERLOCAL final goal is to become a movement of people connecting resources and labour locally, but having an international Eco through the system platform. The system develops through a constellation of activities, including local productions, production tours and lecturers happening in every part of Europe. Doing so it helps local economies, promotes local craft traditions and encourages a new production mentality.

Please give information about the key objectives of your concept/idea in terms of aesthetics and quality of experience beyond functionality and how these would be met

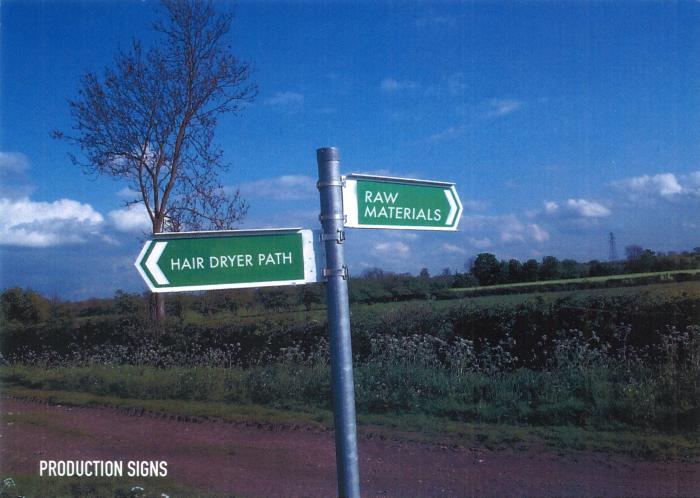

At SUPERLOCAL, form follows context. This means that the object literally arise from the context in which it is made. After mapping all the production facilities available in a given area, which is usually a district size scale (around 3 kilometres) we decide what to make. By hybridising the function of the object and the district availability of materials, craftsmen, fablabs and associations, we define the shape and the aesthetics of every object we produce. Of course such process is mediated by the sensibility and the experience of the designer managing it, but we let our local discoveries and encounters drive our process as much as possible. The final output, which is always a daily life object, has an aesthetic which is defined by the function and the meaning of the object itself. Let me give you an example: as the idea behind the hair dryer 1.0 is to open up the production line, the object has a transparent glass-made body to let people look into it, the same way they can navigate its production line within the system platform: www.super-local.org. Every object produced via the system is also designed based on the production experience which comes with it: it describes a trajectory within a district including interesting workshops, stores, peoples, materials and techniques. The participants to the production tours we organise in various towns in Europe experience the production during this one day experience ending with a self-made daily life object and with a memory of the production knowledge that comes with it. We believe that getting to know how the objects are made encourages a more sustainable evolution and a more aware relationship with the goods we use every-day.

Please give information about the key objectives of your concept/idea in terms of inclusion and how these would be been met

Firstly, the production lines suggested by SUPERLOCAL are driven by the production facilities and the materials that are locally available. Secondarily, the objects are always the result of a study about the local manufacturing traditions and knowledge linked to specific areas. They usually come in a set including 3/4 objects and giving an overview about the materials and the manufacturing processes that are most common to the given area. After mapping, designing and producing, the last phase is the production tour, where we engage with whoever wants to know an area from the production point of view and to dive into an hands-on experience. At the end of the tour people end up with a customised, fully functioning and self-made object.

The tours have been already organised in Eindhoven (NL) in 2016, in London (UK) in 2017, and in Bolzano (IT) in 2018. This experience is a starting point for a more aware vision on objects and on production in general. The tour works on two levels: firstly creating a stronger emotional bound between the consumer and the object he/she made during the tour, secondarily unveiling the socio-economic context and the knowledge which are embedded in the object made according to the SUPERLOCAL system. Another key aspect, which is meant to work more on the long-term, is creating a collaborative community of people sharing the same geographical and cultural area. We experienced the project as very fruitful way to connect producers and consumers on one side and also producers between themselves on the other.

Please explain the innovative character of your concept/ idea

There is a growing desire to know more about the supply chains of the objects we buy and consume. There is a more critical and aware attitude towards what we consume. Therefore, every supply chain of the objects produced via the SUPERLOCAL system is accessible through the system platform (www.super-local.org). Already fifteen objects have been made in four different locations in Europe: Eindhoven, Rome, London and Bolzano. Nevertheless, the project can be implemented everywhere. The platform allows citizens of a certain geographical area within a specific economic and social context to locally produce objects meant and designed for those locations. Every designed object, produced through the system, is the direct representation of the context where it has been made and its production possibilities. On the manufacturing point of view, the objects combine digital manufacturing techniques and traditional ones, suggesting a future vision on crafts.

SUPERLOCAL opens up a new possibility in the way we consume and produce goods, in addition it allows new interactions with objects, giving them a new social value. The economic theory which lies behind the project is “Ethonomics”, in fact, production doesn’t happen just to maximise efficiency, but it also addresses social and environmental viability. Moreover, it is always linked to a rigorous analysis of the production context. Being an alternative to the usual consuming systems, it supports local economies and small enterprises, such as workshops, cooperatives, maker spaces and small suppliers.

Please detail the plans you have for the further development, promotion and/or implementation of your concept/idea, with a particular attention to the initiatives to be taken before May 2022

We would like to open up a new project phase now, which implies a more medium/long term vision. In fact, we are going to prototype the first SUPERLOCAL offline production hub.Such place will coordinate the local production lines which are activated in the neighbourhood and will also function as a hub for organising activities, workshops and classes reaching out and in direct contact with the town existing networks. We would like to test and prototype such model as we feel it might become a scalable system which can be implemented elsewhere.The hub works as a mediator between the citizens and the production/crafts networks of the town and would be funded by the organisations dealing with the city-branding, cooperatives and craftsmen union associations. Such hub will be based in Turin, which is a town based in the north-west side of Italy and which has a long history of industrial city, mainly devoted to car manufacturing. In fact, the city hosts the head quarter of FIAT, the main Italian car manufacturer.During the last years, following a global economic trend, the company merged with General Motors.This changed the company into a multinational company having its legal headquarter in The Netherlands.In other words Turin is now turning into a post-industrial town, which still has the industrial and crafts knowledge and infrastructure.Once more with the on going pandemics, the city is looking for new ways of redesigning itself.I’ve been mapping already some craftsmen operating in the city as well as getting in contact with associations dealing with city branding, tourism, and crafts related projects and researches.They declared their best intentions in helping funding the project in order to offer some production tours to enrich the touristic offer, which is even more urgent now that tourism is in pause due to the pandemics.It is a perfect moment to question and redesign the way we have been living the cities, and we believe that SUPERLOCAL can give its contribution.

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed concept/idea has not been proposed for the New European Bauhaus Rising Stars Awards more than once in the same category.

Yes