I. SUMMARY INFORMATION

Project

267731

Status

Submitted

Award category

Products and life style

You want to submit

NEW EUROPEAN BAUHAUS RISING STARS : concepts or ideas submitted by young talents (aged 30 or less)

Project title

MicroCell

Full concept/idea title

Microbial fermentation turning agro waste into food and packaging products

Description

Microbial fermentation practices for thousands of years transform organic and edible matter into various and healthy foods. By collaborating with yeasts and bacteria, local agro-waste can be turned into valuable prebiotic foods and compostable materials. SCOBY, an acetic mother used in Kombucha brewing, can turn often discarded ‘lower value’ by-products into valuable co-products while enhancing (g)local resources, territorial resilience, and contributing considerably for more circular cycles.

Where is your concept/idea being developed or intended to be implemented in the EU?

Italy

South Tyrol

Piazza Università 1

46°29'36"96 N

11°20'4"56 E

Bolzano

39100

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your concept/ idea

Current production logic is based on the generation of products and waste. Durable materials that often contain products are dispersed polluting the environment. However, in nature, the "waste" of an organism is the nourishment of another. This principle is called cradle-to-cradle and aims at circular and renewable practices: what if byproducts become co-products with equal value? Project MicroCell is the continuation of an interdisciplinary project called 'InnoCell' developed at unibz. Design and food technology came together to address the local waste reality around apples: in South Tyrol almost 12% of European apples are cultivated and processed, related scraps are downcycled into fertilizer.However, these scraps are a valuable resource that can be used to prepare a liquid to nourish bacteria and yeasts present in SCOBY (acetic mother used to brew Kombucha beverage). They ferment the liquid and produce microbial cellulose (MC) that appears as a jelly membrane. During the InnoCell project the production of MC was investigated: an open source bioreactor was developed to democratize its accessibility. MC was processed in diverse states: it was discovered that MC can be turned into a powder that opens promising further processing like the making of compostable sheets, and solid foam through methods that were specifically developed. MC can be used as a locally crafted alternative to substitute plastic foils and polystyrene packaging blocks. Another fundamental finding is that MC obtained from apples has special prebiotic qualities making it a promising substance for new food products. MicroCell aims at further investigating specific food possibilities (ingredients, snacks and more common food staples) and foam packaging (electronics, cosmetics, filling chips) directions. MicroCell's vision is that through microbial upcycling of local resources EU territories could improve circularity and enhance their resilience.

Please give information about the key objectives of your concept/idea in terms of sustainability and how these would be met

In the close future critical scenarios regarding food accessibility and material production could arise therefore, renewable processes need to be developed, iterated and made accessible. Ideally, they should be carbon neutral, benefit the environment and its populations. SCOBY nourishes on diverse sugars so, different sources like exhausted organic mass (hops and molasses) fruit and vegetable peels can be used for the process adapting to territories, their cultivations and/or industries: South Tyrol could use apples while Sicily could f.i. use citrus generating cellulose with customized properties. Indeed, apple MC is fiber-based and shows prebiotic and antioxidant characteristics (based on unpublished data provided by unibz - Micro4Food Lab) while having a smell resembling ‘caramel’ and a slightly acidic taste with a crunchy to chewy consistency suggesting promising wholesome food products. Differently, MC obtained from tea and sugar has mechanical qualities that are highly suitable for packaging materials. Instead of becoming fertilizer, local agro- waste can be used to make renewable products to be consumed locally possibly having a smaller impact than imported single-use alternatives. Moreover, MC scraps themselves can be easily and directly recycled maintaining circularity within the process. While MC foods would nourish human (and non-human) bodies, fully compostable single-use packaging of sorts could be dispersed in the environment benefiting the soil. MicroCell aims at collaborating with Labs at unibz in order to investigate technical qualities and durability of MC in diverse states (durability of layers is around two years) to refine its application possibilities. Moreover, scale-up perspectives will be discussed with InnoCell partners in other EU countries, local corporations and consortia to understand and improve possible implementation models and scenarios.

Please give information about the key objectives of your concept/idea in terms of aesthetics and quality of experience beyond functionality and how these would be met

MC is a material with unique and varied qualities. Being characterized by microfibers it has valuable mechanical and aesthetical qualities. As the cultivation is water-based, the colour it takes mostly depends on the nourishing source during the fermentation process: MC grown from apple scraps acquires an orange to brownish colour while, when it is obtained from beetroot scraps broth is vividly purple. However, more color possibilities can be achieved by using pigments in post-processing. In InnoCell purification techniques were investigated to depigment MC with the aim of opening further aesthetic opportunities and structural characteristics. When MC is dried it appears translucent with a tactility that ranges from rigid to smooth and flexible, resembling a hybrid material between leather and plastic. MC turned into foam can also have pleasant shades and present itself as smooth and crunchy. In addition, MC shows a very effective capacity to acquire the texture of the surface on which it dries. Diverse three-dimensional shapes can be achieved through folding two-dimensional surfaces and with cold/hot molding and foam molding. MC substances have a visual and tactile organic and natural feel which characteristics can be seen as a communicative quality that can express naturality and compostability suggesting to the user how to dispose of them efficiently. Implemented MC packaging could be crafted locally to package or contain local foods made potentially with their scraps creating a strong relation between content and container while enhancing territorial bonds. Also non-food packaging would as well communicate the producer commitment to sustainable aims and values. MC materials would be completely compostable lending themself to be directly used as a fertilizer being composted or simply dispersed in the garden.

Please give information about the key objectives of your concept/idea in terms of inclusion and how these would be been met

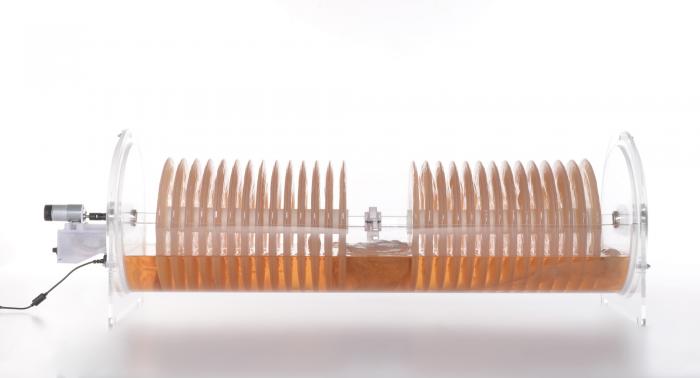

As global interest and acknowledging MC’s potential, the need for efficient and optimized production and cultivation methods becomes more acute. The most common production method is currently based on static fermentation: nourishing liquid and a SCOBY are inserted in a static tank for the duration of the fermentation cycle (7-21 days) after which the jelly which develops on the top surface is harvested. However, this method is highly laborious and requires a large cultivation surface. Instead, scientists have identified another method called ‘rotating disk bioreactor’. It is made of an array of disks mounted on a rotating shaft immersed into the nourishing liquid. In this way MC grows directly on the disks optimizing the volume as well as the oxygenation stimulating the growth. Moreover, monitoring and adjusting the fermentation is easier. Based on this principle, the InnoCell design team developed the InnoCell Bioreactor (IB) consisting of a module that is open-source in order to be reproducible by anyone and adaptable to smaller and bigger production scales. The IB is made of accessible materials and components that enable anyone interested to make one own and use it to produce MC extending circular aims on social levels. People would in this way, have the access and possibility to use byproducts to grow food or materials and to further experiment. MicroCell aims at finalizing the open-source website providing all the guidelines and instructions to make the IB. Moreover, Fablabs would be contacted in order to introduce the potential of making DIY compostable materials with own IB in order to serve as physical accessible platforms fostering knowledge democratization. In this way, citizens would be empowered to reproduce and/or iterate and adapt IB modules, to know MC substances and potentially initiate new projects. Also, InnoCell partners in other EU countries, local corporations and consortia will be invited to consider implementation scenarios based on IB.

Please explain the innovative character of your concept/ idea

SCOBY fermentation fosters a vision in which territories could become more resilient and circular starting from their approach to local discarded resources. By partnering with microorganisms, humans would integrate natural processes into artificial production generating highly versatile microbial cellulose with custom properties according to nourishing sources. The current perception of byproducts as waste could consequently change into co-products as resources with equal value. Low-km new prebiotic foods and compostable materials with a short life cycle will be made and consumed locally augmenting territorial values. In this way, the value of local resources would be recognized and enhanced benefiting not only humans but also manufacturing processes and the (g)local environment. Specifically, the valuable potential of apple obtained MC used for diverse food products is based on its antioxidant and prebiotic qualities discovered during InnoCell research. These results are not yet disseminated and such products are not yet in the market however, MicroCell aims at investigating food applications also in relation to local culinary tradition. In regard to non-food applications, InnoCell's in-depth investigation into purification, grinding and foaming techniques brought up and refined methods that are not yet explored within the design field. For instance, in the state of powder/flour, MC becomes easy to preserve and suitable for many processing techniques, possibly adapting to manufacturing methods like layering and injection molding. Purified or chemically treated cellulose could enable more aesthetic possibilities and applications. Eventually, MC-based foam could replace synthetic polymers in multiple packaging typologies. These principles and application scenarios have a strong focus on knowledge democratization and social empowerment through open-source practices that can be adapted to local areas, their resources and production systems.

Please detail the plans you have for the further development, promotion and/or implementation of your concept/idea, with a particular attention to the initiatives to be taken before May 2022

While the vision and applications iterated with InnoCell are the result of its unique investigation path, MicroCell aims at refining, deepening and finalizing MC applications and overall dissemination aspects. MicroCell is a follow-up of the InnoCell project conducted by the applicant at the Faculty of Design and Art of the Free University of Bozen/Bolzano. Initiatives planned within May 2022 concern the development of an open-source online platform aimed at making the instructions of the bioreactor and the material experimentation reports, food and material-making recipes accessible and comprehensible to anyone. Moreover, Fablabs, InnoCell partners, local companies and consortia will be involved in the process related to the following steps and dissemination of the InnoCell Bioreactor in order to foster and envision possibilities around models of MC production integration within the system (such as in-house integration and distributed system). An iterative MC experimentation will be enabled by the assembly of new bioreactor units aimed at producing MC yield. MC obtained from apple scraps will be investigated aiming to identify valuable food perspectives together with interdisciplinary experts (food technologists and chefs) with a special focus on local culinary tradition. Moreover, processes concerning foam making and its manufacturing will be further iterated in order to identify and refine moulding procedures. Overall, technical data concerning MC in different states will be collected in collaboration with academic Labs in order to identify durability and possible other valuable properties providing the ground for scenarios and applications refinement. Foreseen dissemination also involves an exhibition at Vitra Design Museum in Switzerland and another one possibly held by MIT in Massachusetts. Scientific articles aimed at open-source dissemination are in the process of being published and additional would be written.

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed concept/idea has not been proposed for the New European Bauhaus Rising Stars Awards more than once in the same category.

Yes