I. SUMMARY INFORMATION

Project

267624

Status

Submitted

Award category

Techniques, materials and processes for construction and design

You want to submit

NEW EUROPEAN BAUHAUS AWARDS : existing completed examples

Project title

PULRON Thermoplastic Coating

Full project title

PULRON Thermoplastics Coating - anticorrosion metal protective coating

Description

PULRON Thermoplastic coating provides to metal ultimate protection against corrosion in exterior. It last for decades without any changes in quality, colour and gloss. Material is environmentally friendly, easy to use and easy to repair.

Where was your project implemented in the EU?

Slovakia

Nitra

Vodna

Nitra

94901

When was your project implemented?

Has your project benefited from EU programmes or funds?

No

Which programme(s) or fund(s)? Provide the name of the programme(s)/fund(s), the strand/action line as relevant and the year.

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your project

PULRON is thermoplastic coating powder which has been specifically designed to provide a long lasting durability to metal for exterior and general applications.

Currently there is no other surface coating which offers higher resistance against corrosion, chemicals and UV radiation.

It is based on modified Polyolefins which can be applied over mild steel, aluminium or galvanised steel by electrostatic spray, fluidised bed, flame spray or flock spray system.

It is best coating for metal structures in harsh environments. Excellent wear and tear characteristics. Highly resistant to UV fading, bird droppings and peeling. Outstanding performance agains salt, sand, water, UV, ice and impact degradation. A very good electrical insulation.

ADVANTAGES OVER TRADITIONAL METAL SURFACE TREATMENTS

•Extremely adhesive to metal

•Superior corrosion resistance.

•Superior impact resistance.

•Detergent and chemical resistance.

•Flexibility and elongation of the coating up to -60C degree.

•Electrical insulation.

•Chip resistance.

•Aesthetically-superior finishes.

Please give information about the key objectives of your project in terms of sustainability and how these have been met

Excellent quality of PULRON thermoplastics coatings ensures a long life time of metal work in exterior. Key coating properties:

- Fully UV resistant: Attractive, color-stable finish that lasts for decades

- Excelent corrosion resistance: Long-term corrosion protection agains abrasive effects of salt, sea water, sand and sun. Corresponds to C5-M, C5-I and Im3 corrosion categories

- Excelent environmental credentials: No VOCs, no TGIC, no halogens, no plasticizers, no isocyanates, and no heavy metals

- Easy to use

- Flexible: maintains flexibility even at -60C without cracking

- Superior chemical resistance

- Easy cleaning. Anti -graffiti feature

- Strong surface: Resistant to impact and abrasion

- Hygienic: Slow rate of growth mildew and funds compared with other coatings

- WRAS approved product options in compliance with drinkable water legislation

- Excelent adhesion to metal

- High peeling and cracking resistance

- Repairable

Please give information about the key objectives of your project in terms of aesthetics and quality of experience beyond functionality and how these have been met

Pulron thermoplastic coatings can be made in various RAL colours and metallic colours. Final finish is very aesthetic and contemporary.

Appearance and Technical Characteristics

Smooth, durable and long-lasting coating;

Antislip version available;

Colour and pattern uniformity which will last for many years to come;

Easy to repair if accidentally damaged

Eco Friendly;

No porosity.

BARRIER PROPERTIES (vapors, liquids, chemicals)

Resistance to penetration of liquids (anti-osmotic characteristics);

Excellent resistance to chemicals (acids, alkali, solvents)

WEATHERING PROPERTIES

Excellent resistance to adverse weather conditions;

Outstanding UV protection;

Excellent behaviour in case of fire (material that would not easily catch fire);

Stain resistance, there are no pores for calcium, rust or other staining agents to grab or imbed into;

Anti-bacterial properties

MECHANICAL PROTECTION, IMPACT RESISTANCE, ABRASION RESISTANCE

Excellent Adhesion;

Abrasion-resistance (Taber ASTM 60mg/500g);

Remarkable elastic properties (elongation to break: 500%)

Excellent resistance to blistering, chalking, peeling, cracking and other signs of deterioration in normal use;

Excellent flexibility, even at very cold temperatures;

Resistance to cold (-60C).

Please give information about the key objectives of your project in terms of inclusion and how these have been met

PULRON thermoplastics coating can be widely used. From corporate buildings, streets, underground to children playgrounds. Everybody can benefit from outstanding quality and life time of this type of metal surface treatment.

Please give information on the results/impacts achieved by your project in relation to the category you apply for

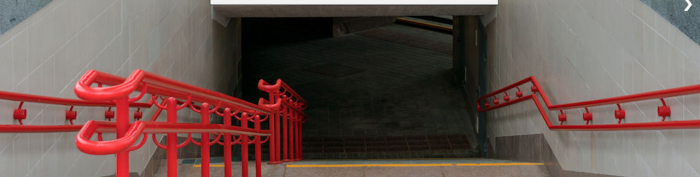

PULRON thermoplastics coating are mainly used in Architecture and Engineering. Your may see them for example on following applications:

- steel construction

- metal fences

- hand rails

- street furniture

- stadium seating

- marine environments

- swimming pool coatings

- playgrounds

- battery boxes and racks

- cable trays

and many others

Please explain the way citizens benefiting from or affected by the project and civil society have been involved in the project and what has been the impact of this involvement on the project

Termoplastic coating solves problem with metal corrosion on item which surrounds us in exterior - metal fences, street furniture, lamp posts, hand rails, bicycle holders and many others. Thermoplastics coating on metal structures will last for decades without need to repair. It will save energy for repairs, and will be aesthetic for long time.

PULRON thermoplastics coating makes word more colourful, sustainable and ecological for everyone.

Please highlight the innovative character of the project

Thermoplastics metal coatings is a new, progressive way for ultimate protection of metal against corrosion. It is easy to use with electrostatic spray gun in every powder coating plant. There is no need for primer. Itś just one way application.

Please explain how the project led to results or learnings which could be transferred to other interested parties

Wet and powder paintings are traditional and widely used surface treatment of metal. But do not meet ecological and sustainability requirements. Thanks to research and development thermoplastic powder coatings were invented to provide best solutions for now and future.

Since itś quite new type of coating not everybody is aware of this progressive and function type of coating. We would like to arise awareness of it, we promote it on internet, on exhibitions (now limited way due to pandemic situation) and we welcome New European Bauhaus initiative as a perfect way to let know about thermoplastic coatings because we believe that this can make our environment better, more aesthetic and sustainable.

Is an evaluation report or any relevant independent evaluation source available?

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed project has not been proposed for the Awards more than once under the same category and that it has not been subject to any type of investigation, which could lead to a financial correction because of irregularities or fraud.

Yes