I. SUMMARY INFORMATION

Project

268216

Status

Submitted

Award category

Techniques, materials and processes for construction and design

You want to submit

NEW EUROPEAN BAUHAUS AWARDS : existing completed examples

Project title

ERDEN PURE Walls

Full project title

Prefabricated Unstabilised Rammed Earth Elements for a Sustainable and Circular Building Industry

Description

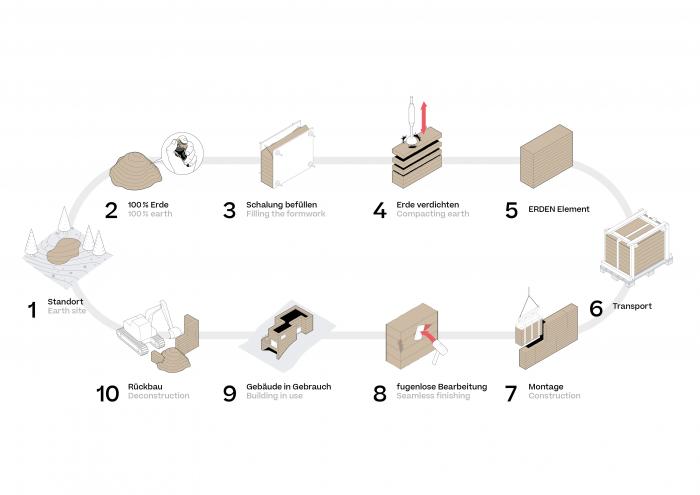

Steny ERDEN PURE sú prefabrikované stavebné prvky z nestabilizovanej nabíjanej zeme vyrobené zo 100 % prírodnej zeminy a sú plne recyklovateľné. Konkrétne je materiál nestabilizovaný, čo znamená, že do zemnej zmesi sa nepridáva žiadny cement. Toto kľúčové rozlíšenie umožňuje stenám PURE pasívne regulovať vnútornú teplotu a vlhkosť. Tieto steny odstraňujú nežiaduci zápach z priestorov a ponúkajú materiál jedinečný na dotyk, ktorý je vhodný pre súčasnú architektúru. Surovinou je zemina vykopaná z miestnych stavenísk, obvykle ide o odpadový produkt, ktorý sa potom upravuje pomocou piesku, štrku alebo hliny, aby bol vhodný na stavbu. Zmes sa naleje do dlhých foriem debnenia a špeciálne vyvinutým strojom sa naraz nabíja po jednej vrstve. Každá vrstva hotovej steny sa potom rozreže na veľké časti a prirodzene sa suší, až kým nie je pripravená na prepravu na miesto a použitie vo výstavbe, ktorá prebieha podobne ako pri tehlách. Proces prefabrikácie optimalizuje výrobu a výstavbu a transformuje starodávnu techniku s vysokým podielom práce na takú, ktorá dokáže produkovať konzistentný a vysokokvalitný výstup, ktorý je schopný konkurovať iným priemyselným stavebným materiálom. Táto technika, ktorú vyvinul Martin Rauch a jeho spoločnosť Lehm Ton Erde (hlina, íl, zemina), je v úplnom súlade s udržateľnými stavebnými zásadami „od kolísky ku kolíske“.

Where was your project implemented in the EU?

Austria

Vorarlberg

Eichengasse 23a

47°11'58.1"N

9°41'41.0"E

Schlins

6824

When was your project implemented?

Has your project benefited from EU programmes or funds?

No

Which programme(s) or fund(s)? Provide the name of the programme(s)/fund(s), the strand/action line as relevant and the year.

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your project

Earth may be the world’s oldest building material. Some form of earthen construction can be found on nearly every continent and in nearly every country. It was valued for its high compressive strength, ease of production and repair, availability in raw form in almost infinite amounts, acoustic absorption properties, humidity regulation qualities, high thermal mass, and aesthetic appeal. As the western world became industrialised, however, rammed earth fell out of favour due to an intensive labour process and competition from concrete. After 35 years of building with earth, pioneer and expert Martin Rauch has a technique and know-how that decouples rammed earth from its high labour drawback. Prefabricated unstabilised rammed earth (PURE) walls - unstabilised, meaning without any cement - are a structural building element that cut production costs by 50% and reduce production time by 65% compared to conventional rammed earth production. The 100% earth, 100% recyclable wall elements are the only building material that align fully with sustainable building principles such as the cradle-to-cradle concept.

The PURE elements are produced in formwork 40-50 m long and 1.4m high. Our specialised machine is affixed to the immovable side of the formwork. It robotically distributes the material into the formwork and then rams the poured material. The machine pours a layer of material mixture 12-15 cm thick and then compacts the layer, reducing it to 8-10 cm. Depending on the desired finish and use, these are altered to specification. The rammed wall is cut into large elements which can be transported to site and built up like bricks. The prefabrication process not only optimises production and the construction, it also allows for material consistency and higher-quality output, which are particularly important for achieving industrialised norms and standards to compete with other standardised, industrialised building materials.

Please give information about the key objectives of your project in terms of sustainability and how these have been met

The PURE walls project was developed and continues to develop a building material with a deep ethos of sustainability in multiple aspects. The rammed earth mixture is innately environmentally sustainable. It is principally made up of excavated earthen material from building sites that is sieved to particle size that is suitable. Depending on the excavation site, some tweaking of the raw material with sand, gravel, or clay might be needed. But that is the raw material. Our key objectives in terms of sustainability with PURE walls are not to make the building material more sustainable, but to effectively modernise the processes around its production and implementation in order to make rammed earth more competitive in the marketplace; to reduce the building industry’s reliance on concrete and brick.

Firstly, we close loops in the building cycle. The material we use to produce walls is excavated material from local building sites. This material is usually transported to southern Germany, at cost, for dumping. With our partner Kessler, we take this material, sieve out the portion we can use - usually around 60% or raw excavation - and then condition it for use. This creates a mutual benefit for us and local excavators, reducing waste and emissions from freight.

Secondly, demolished PURE walls are fully recyclable. The material simply needs to be conditioned with water again and can be used to rebuild wall elements to the same quality every time. And what is not needed can be returned to the ground without treatment as it contains no chemicals and is porous. This is rammed earth’s greatest advantage.

Finally, our production site in Schlins uses hydroelectric power from the canal adjacent to the site and a solar thermal heating system heats the factory, leaving only transportation as an emissions source in our whole operation.

Please give information about the key objectives of your project in terms of aesthetics and quality of experience beyond functionality and how these have been met

Unstabilised rammed earth has the major advantage that it is essentially water soluble. While this may sound frightening for a building material, in reality, it is an advantage. There are many strategies to mitigate against erosion. Our experience has taught us how to detail rammed earth construction in the European climate. Well detailed buildings have no issue with longevity. The advantage comes when it comes to finishing surfaces. Rammed earth facades and interior walls can be made jointless or seamless through a process of retouching. This technique takes loose, earth-most material from the same stock as the wall and hammers that material into the seams between PURE elements. This process can be repeated for corners, window edges, and any other edge interface. Once it dries, huge wall faces can appear as an unbreaking surface of textured earth. This finish can be seen in the Ricola Herb Centre project completed near Basel in 2012. Designed by world renowned architects, Herzog & de Meuron, the building facade stretches over a hundred metres with no movement joint. The retouching technique allows the material to form sharp edges as well, giving the desired contemporary aesthetic for many designers. Earth’s natural texture is also a major draw card for designers and architecture. The PURE wall elements can be made as thin as 7 cm which work perfectly as interior lining panels.

Please give information about the key objectives of your project in terms of inclusion and how these have been met

Of course, rammed earth is inherently ecologically sustainable, but we’ve made sure to address social and economic aspects of sustainability in our initiative too. We do this in several ways.

First, our approach takes full advantage of the rich heritage of baukultur or ‘building culture’ in Vorarlberg. We engage with local craftsmen, carpenters, ceramicists, and more, to create meaningful spaces with earth that people want to live in. This process of co-creation breeds a kind of built form that is engendered with a peoples’ way of living and aesthetic. This type of architecture is called Baukunst or ‘building art’ in German, and it is a uniquely regional approach. It is interdependent with the community of makers and therefore fosters greater inclusion than the traditional developer-architect development model.

Second, we’ve tried to address the relative lack of know-how in rammed earth construction by starting the ERDEN Schule - the Earthen School. The initiative has a vision for the long term, to educate young, train the willing, and engage with the old within the community. The mission is to generate general knowledge around the benefits of earthen construction and sustainability. Whereas every person tacitly understands how you would build something with bricks or how the properties of timber allow you to form structures, this basic understanding is missing for earthen construction. Programs offers school children “claystorming” sessions, to feel the material in their hands gain the feel for its behaviour by modelling their own designs. Training university students already takes place on-site through internships. Whereas other trades have established training programs and apprenticeships, the ERDEN Schule aims to fill this gap for rammed earth through practical experience and mentorship. Finally, design professionals and older folk from the community are invited to seasonal “Erdenfest” workshops as an event to share ideas for rammed earth in a lively setting.

Please give information on the results/impacts achieved by your project in relation to the category you apply for

The results of the project are difficult to measure. It is an ongoing development and is continually evolving. What we know is rammed earth has an unmatched interior climatic advantage as a building material. The aesthetic and architectural demand for it are high. It’s carbon footprint is lower than any other material out there. What’s left is to study longer term projects and evaluate how the production process can be made efficient enough or be supported and subsided to a point where real widespread uptake of rammed earth can have an environmental impact.

Please explain the way citizens benefiting from or affected by the project and civil society have been involved in the project and what has been the impact of this involvement on the project

Thinking about sustainability goes further than environmental considerations in our work. We have implemented an alternative financing method for the project known as a Vermögenspool (wealth pool). It is a sort of credit union to support the local community and our continued operations. The cooperative and member operated financial model offers people a stable investment on relatively small lumps of savings. People who wish to break from the extractive capital investment dynamic of the established financial sector are able to place their money in a project they believe will support their community. In our case, the invested money is guaranteed against our factory infrastructure. The majority of the investors are from the town and local Vorarlberg region. This financing model relies on an interpersonal connection between investor and investment. They get to see where their money is placed, giving peace-of-mind. We have raised one million in capital with the Vermögenspool cooperative and have direct engagement with the investors as they form part of the local community. It has created a trust between business and citizen.

Please highlight the innovative character of the project

The groundbreaking innovation of PURE walls lies in the implementation of our acquired knowledge of prefabrication into a project-independent element system, the consistent use of rammed earth as a load-bearing structural element, and the further development and improvement of the insulation technology and the production process. The PURE elements are executed in formwork 40-50 m long and 1.4 m high. When ramming with our specialised machine - affectionately named Roberta - developed in collaboration with Reisch engineering ltd. (AT), the machine is affixed to the immovable side of the formwork. It robotically distributes the material into the formwork as well as tamper the poured material. The machine pours a material mixture in 12-15 cm thick layer increments with particles of this mixture not exceeding 3.2cm in diameter. When it is compacted, the layer will reduce to 8-10 cm. The prefabrication process not only optimises production and the construction; it also allows for material consistency and higher-quality output, which are particularly important for achieving industrialised norms and standards to compete with other standardised, industrialised building materials.

By not using cement, this process ensures water used in production is free from toxic chemicals, the batch size can be far larger, and allows the finished product to regulate indoor humidity. PURE elements serve as a massive thermal material, an optimal heat sink for passive temperature regulation. Not only is the embodied energy of rammed earth low, but so are the maintenance costs of rammed earth buildings. The PURE elements are transported to a building site layed like giant bricks, eliminating the need for ramming in situ bringing rammed earth in line with BIM and leading industry practices.

Please explain how the project led to results or learnings which could be transferred to other interested parties

The project continues to grow and evolve. Part of an innovative effort such as this is that it must continually be revised to meet needs better and work more effectively. Rammed earth offers an unparalleled combination of quality of living experience, functionality, and circularity. What we’ve learned is the demand and interest in the material is there, it’s the bottom line, the question of cost that remains a hurdle. Prefabrication has released some of this pressure in comparison to in situ production, however, economy of scale still remains an issue. At the moment, we source the raw material, condition it, mix it, plan the production, manufacture the elements, ofter design services for it, and often need to construct the elements too. If you compare this process to concrete production, for instance, each stage of the process is undertaken by separate organisations and therefore can be made more efficient. One thing we’ve learned is we need partners. Earth has no lobby and as such struggles enter the mainstream of building materials. It needs explore, recognition, and government support if the material is to be used to its full potential, as truly dependable and modern sustainable building material.

Is an evaluation report or any relevant independent evaluation source available?

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed project has not been proposed for the Awards more than once under the same category and that it has not been subject to any type of investigation, which could lead to a financial correction because of irregularities or fraud.

Yes