I. SUMMARY INFORMATION

Project

268045

Status

Submitted

Award category

Techniques, materials and processes for construction and design

You want to submit

NEW EUROPEAN BAUHAUS RISING STARS : concepts or ideas submitted by young talents (aged 30 or less)

Project title

Custom Station

Full concept/idea title

Creating a more sustainable and inclusive railway infrastructure, for a better connected Europe

Description

With Custom Station, we propose a bold new way of constructing railway infrastructure. We combine technologies like 3d-printing with the railway networks, to create mobile construction plants. These can build railway infrastructures where they are needed, using local resources and adapting to the needs of local communities. This combination of systemized fabrication and crafting buildings locally allows for a more sustainable and inclusive way to create the infrastructure of the 21st century.

Where is your concept/idea being developed or intended to be implemented in the EU?

Netherlands

Rotterdam

Delftseplein 27j

51.925110

4.473190

Rotterdam

3013 AA

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your concept/ idea

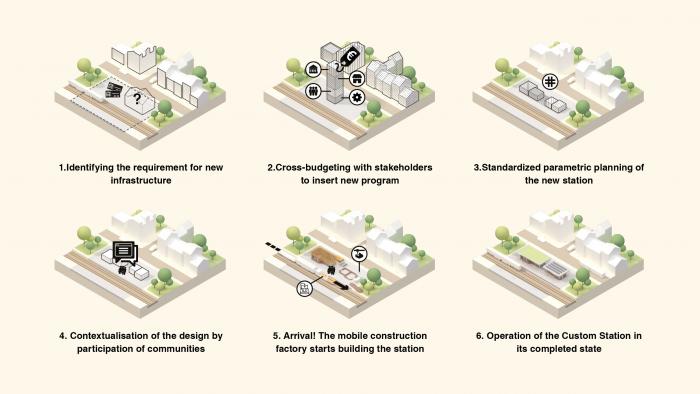

Within the European Green Deal, the European train networks play a significant role in reducing carbon emission and energy consumption caused by the transportation sector. Yet, many regions are challenged by putting in place the railway infrastructure that is needed for a vision of Europe connected primarily by train. For this reason, we want to contribute to a sustainable and inclusive vision of the future of the European railway system, by proposing a new way of constructing the railway infrastructure of tomorrow.

To do so, our project Custom Station is combining two things: Digitally driven construction technology, such as additive manufacturing and CNC-cutting, and the transportation potential of the existing railway network. The result is a mobile construction plant, equipped with the machinery to construct infrastructure exactly where it is needed, with the resources available on site. Not only can this drastically reduce the amount of carbon emission and energy caused by the transportation of raw materials to centralized production facilities or the construction site, as local materials can be used for most of the fabrication processes.

This highly localized manufacturing of buildings, based on systemized digital and fabrication processes, brings together the best features of both in-situ and prefabricated construction. On one side, the precision of machine-based fabrication and a high level of control over their output, and on the other side the ability to locally adapt to the conditions of the site. Furthermore, the flexibility of the construction method allows to adapt the architecture of these buildings to the communities and stakeholders around them – programmatically, financially and aesthetically.

This merger of the local and the standardized merge in a new vernacular architecture for infrastructure buildings in the 21st century – mass-localized, sustainable and inclusive, bringing the vision and goals of the New European Bauhaus onto rails.

Please give information about the key objectives of your concept/idea in terms of sustainability and how these would be met

Custom Station is a sustainable evolution of the way we create railway infrastructure for several reasons. These different reasons can be categorized into benefitting from the standardization of the construction processes used, and benefitting from the return to a highly localized construction itself.

The standardization of the construction processes includes the technologies and software behind the fabrication methods used, and the systematic utilization of the existing railway network. Additive manufacturing and CNC-cutting are highly efficient and precise methods of fabrication. Not only is the processing residue of materials eliminated, but also the chances for constructive errors made on site is reduced drastically, as all constructive principles applied can be prototyped and optimized before the mobile construction plants replicate them on site. By transporting machinery, equipment and staff exclusively on the rail network, a significant reduction of emissions is possible compared to transportation on roads.

Furthermore, localized construction can result in significantly reduced environmental impact, mostly due to the elimination of resource transportation. Instead of delivering raw materials into factories, and the finished components onto the site, locally harvested wood, used for the CNC-processes, and locally extracted earth, providing the basis for additive manufacturing, provide the resources required for most of the construction. These materials are not only widely available, but also have a smaller carbon footprint in their processing than alternatives such as full concrete or steel construction.

In summary, Custom Station brings together the environmental benefits of both standardized and localized construction. Further research is needed to fully determine the quantitative advantages of this approach, but on a conceptual level it has great potential to create infrastructures in a more sustainable way in the future.

Please give information about the key objectives of your concept/idea in terms of aesthetics and quality of experience beyond functionality and how these would be met

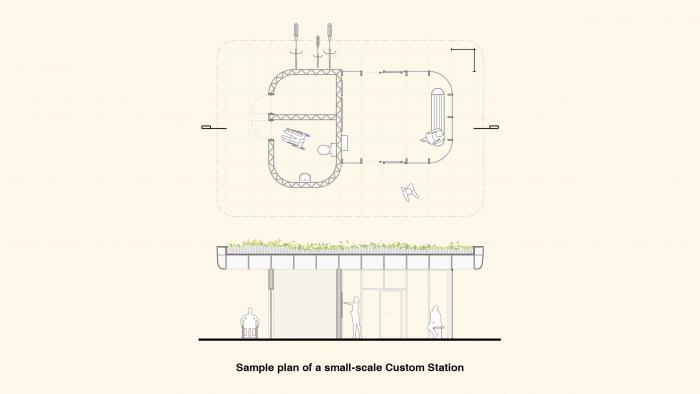

Custom Station is, beyond a strategy for construction process and fabrication, about creating new infrastructure buildings that people can feel connected to. This goal is approached in two ways – for once, by emphasizing and benefitting from the eccentric aesthetic output inherent to the fabrication methods used, and secondly, by allowing the future users of the buildings to co-author the design language of their very own buildings.

The premise of the design articulation of the project is, due to its infrastructural character, a functional one. But caused by the characteristics of the additive manufacturing process, which is the main construction method, a peculiar design language will be embedded naturally into these buildings. 3d-printing on a building scale layers levels of several centimeters of material on top of each other, which are clearly experienceable as an unconventional visual effect. Just this method of fabrication alone attracts the fascination of humans, as it goes beyond what is commonly perceived as construction today.

But this visual effect can be even further emphasized, by programming different patterns into the fabrication script of the 3d-printer on site – a simple step, with an endless number of visual possibilities. Even the color of the 3d-printed structure will differ, following the composition of local soil and filaments added for this purpose. By nature, each building will be unique, whilst all of them will follow a clear and recognizable design logic.

This process even allows to involve the local community in the design conception, by choosing and co-designing patterns and color combinations of their buildings. This is described in more detail below, but this potential is a relevant aspect of how to create an experience for users going beyond mere utility. Instead, a beautiful, contemporary design language informed by their users is crafted, by simply utilizing the tectonic potentials of the applied construction method.

Please give information about the key objectives of your concept/idea in terms of inclusion and how these would be been met

As addressed previously, the involvement of local stakeholders is a relevant aspect of creating new infrastructure which is not only connecting people, but also connected to people. This participation of a local community into the aesthetic articulation of their infrastructure is one part of how Custom Station aims to create a more inclusive generation of railway infrastructure.

Another contribution of the project towards this vision is the involvement of local stakeholders at an earlier stage of the project process, namely the brief configuration for the structure to be built. In this phase, the scope of what a railway station should accommodate programmatically is defined, and the involvement of local residents, organization and businesses in this process can bring significant advantages to the integration of the structure into its place later on. If there is a local need for certain programs or facilities, the station in planning can eventually provide space for this demand.

Not only will an early participation allow for a better integration of the new building, but it will also allow to localize and distribute the economics of a new train station. Instead of infilling the program commonly found in this typology, alternative program that is more suited to local needs can contribute to a socially more embedded infrastructure. Bringing together different public and private stakeholders to cross-finance the extended station/infrastructure buildings for additional program accommodation contributes to create buildings with increased impact on its surroundings and user.

At the same time, the processes of construction as described previously can adapt to different functions within the structures without altering the principles of fabrication. Whether it is a café, a community space or a bookshop, the particular demands of these typologies can be easily integrated in the overall digital planning process and the construction process.

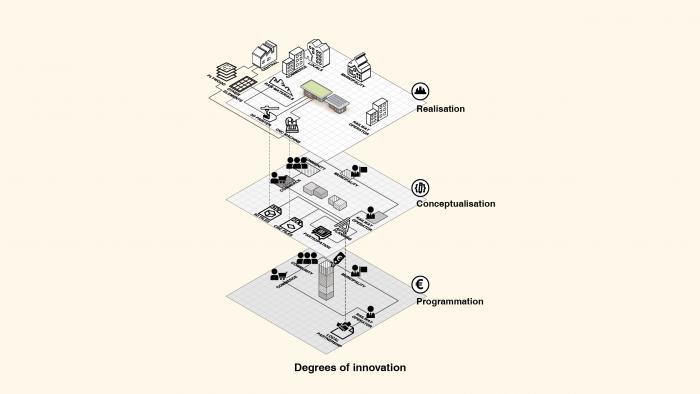

Please explain the innovative character of your concept/ idea

The innovative character of Custom Station can be summarized in advancing mass-customization into mass-localization for the construction of new railway infrastructure. Instead of centralizing the production of building components as done in a traditional prefabrication scheme, a series of new fabrication processes can be intertwined, to allow for a rail-bound, mobile method of building train stations and similar structures. As described above, this innovative approach towards the way we build will bring significant environmental and social benefits for multiple reasons.

Besides this, the model of community participation and local stakeholder engagement proposed in the design conception, building programming and cross-financing of these new infrastructure buildings brings a new aspect to how citizens can contribute and take part in creating the infrastructure meant for them. This concept of participation goes deeper than the participation models currently in used, and can be introduced gradually, once the technological proof of concept has been reached as described in the project plan below.

Besides the conceptual benefits of advancing into mass-localization and new forms of deep citizen participation, there are also the technological aspects themselves, which are underlying the project, and are of highly innovative nature in their own regard. The technology of additive manufacturing on a building scale, although progressing rapidly, is still a relatively young method of construction. Especially when it comes to the 3d-printing of earth concrete, there are many paths to explore. Projects like Custom Station can help to accelerate the development of these technologies, which can have significant environmental benefits in other realms of construction as well. Thereby, we can contribute with Custom Station to the vision for a more sustainable and inclusive built environment as part of the European Green Deal and the New European Bauhaus.

Please detail the plans you have for the further development, promotion and/or implementation of your concept/idea, with a particular attention to the initiatives to be taken before May 2022

Custom Station has a systematic applicability in the realm of railway infrastructure construction. Thereby, a major focus of developing the project further will be a partnership with either ProRail, the government agency responsible for domestic operation and extension of the Dutch railway, or another European network operator. By doing so, we aim to build up research capacity, and investigate the technological, financial and participatory aspects of the project, and start prototyping and proofing the concept in real life applications.

As a first step within the coming 12 months, we are aiming to develop and publish a research report on the conceptual feasibility of using additive manufacturing and CNC-cutting on mobile construction plants, to determine future potential of the technology and application. To achieve this goal, other institutional and private stakeholders active in the fields of additive manufacturing in the Dutch AEC-industry will be addressed, to integrate their experience and expertise in the research we aim to conduct.

After this first research phase, it is planned to communicate the findings of this research in different ways, such as workshops and conventions, to create exposure for the project in media, academia and praxis. Furthermore, if the technological viability is given, we are aiming to develop the first prototypical applications together with ProRail, to test practical applications for a continued development of the project, and to continue developing the participation model for these new infrastructures, once they can be implemented in practice.

In our mid- and long-term vision for this project, the result of the research, prototyping and implementation of Custom Station is not only aimed to create the next generation of railway infrastructure, but eventually also expand a knowledge basis for other fields of construction, to create a more sustainable and inclusive built environment on an even larger scale.

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed concept/idea has not been proposed for the New European Bauhaus Rising Stars Awards more than once in the same category.

Yes