I. SUMMARY INFORMATION

Project

269258

Status

Submitted

Award category

Techniques, materials and processes for construction and design

You want to submit

NEW EUROPEAN BAUHAUS AWARDS : existing completed examples

Project title

Cradle to Cradle-based production

Full project title

An SME’s innovative transition to greener production of sustainable acoustic solutions

Description

The building sector accounts for approximately 40 per cent of the world’s resource consumption. There is consequently a need to produce sustainably and think in circular cycles where waste becomes a new resource. This is the core idea behind the Cradle-to-Cradle design concept on which we at Troldtekt A/S have based our strategy and production of Troldtekt acoustic panels. Since we implemented Cradle to Cradle in 2012, we have proved with tangible results that an SME can also be at the forefront

Where was your project implemented in the EU?

Denmark

EU

Sletvej 2a

Tranbjerg J

8310

When was your project implemented?

Has your project benefited from EU programmes or funds?

No

Which programme(s) or fund(s)? Provide the name of the programme(s)/fund(s), the strand/action line as relevant and the year.

II. DESCRIPTION OF THE PROJECT

Please provide a summary of your project

Troldtekt A/S is a Danish manufacturer of documented sustainable acoustic panels, which consist of wood and cement (cement-bonded wood wool) and which contribute to a healthy indoor climate in buildings.

Our business strategy is based on the sustainable Cradle-to-Cradle (C2C) concept. The vision behind C2C is a world in which manufacturers design their products for a circular economy, as opposed to a linear economy.

Via our C2C certification, we can document that Troldtekt acoustic panels can be safely returned to the biological cycle as a soil conditioner. Our production waste also forms part of the technical cycle as a resource in new cement.

Since the implementation of our C2C strategy in 2012, we have reached a number of milestones:

We have based our production on renewable energy (100 per cent wind power and biofuels in our own boiler).

We have had an unbiased mapping done of the substances in our acoustic panels right down to 100 parts per million. We thus know that the panels do not contain any substances that are harmful to humans or the environment.

We have achieved FSC and PEFC certification, which means that all Troldtekt acoustic panels are certified in accordance with leading standards for responsible forestry.

We have partnered up with our cement supplier, Aalborg Portland, which uses cut-offs (dust) from our production of acoustic panels in its production of new cement.

We have become involved in forums and networks that help promote a circular economy in the building industry – in Denmark, Sweden and Germany.

We have expanded our range of C2C-certified acoustic solutions with design solutions that give architects greater freedom to create sustainable and aesthetic buildings.

Our C2C strategy has made it natural for us to focus on four of the UN Sustainable Development Goals (goals 3, 12, 15 and 17). We joined the UN Global Compact in 2010.

Please give information about the key objectives of your project in terms of sustainability and how these have been met

When we launched our C2Cstrategy in 2012, we set some overall goals:

The strategy was to make a documented difference to the environment and people...

... but it was also to help boost our business and pave the way for growth.

Our philosophy is that an SME can only be engaged in persistent and long-term sustainable activities that make a real difference if this approach is combined with a commercially sound business case.

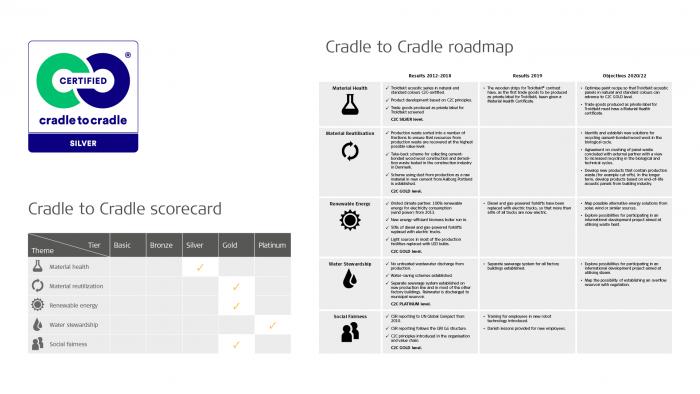

In accordance with the overall goals, we developed a dynamic roadmap that, based on the five criteria categories of C2C, outlines tangible goals for the period 2012-2022. Most of the objectives have been met during the period, and new goals have been added.

To meet these goals, we have made massive investments (a large double-digit million figure in EUR) in innovative and energy-efficient technology. This has enabled us to achieve the following results:

Over the past three years, we have reduced our energy consumption per produced panel by 28.6 per cent, including through investments in high-efficiency drying ovens.

Today, 97.7 per cent of the energy we use in our production comes from renewable sources that do not emit CO2. We get all our electricity from wind power, and the heat used in the drying process is generated by our own biomass boiler. We have also phased out fossil fuels in our trucks on the factory premises.

Dust from the milling of our panels is used by Aalborg Portland for its production of cement – and thus returns to the technical cycle as a raw material in new cement. In 2020, Aalborg Portland received 3,347 tonnes of dust as return loads in the trucks that deliver cement and would otherwise drive back empty from our factory.

All wood used for the production of our panels derives from responsible forestry and is FSC® (FSC®C115450) and PEFC™. certified, and our customers are free to choose between the two standards.

Please give information about the key objectives of your project in terms of aesthetics and quality of experience beyond functionality and how these have been met

Troldtekt acoustic panels are primarily chosen for their acoustic properties. A surface with Troldtekt absorbs 80-90 per cent of the sound that hits the surface, while, i.e., a concrete surface absorbs only 1-2 per cent.

Architects are key target groups for Troldtekt. It is therefore essential that, in addition to the acoustic function, our solutions make a significant difference in two other areas that both these target groups prioritise highly: design and documented sustainability.

When we launched our C2C strategy, it was important for us to implement the sustainable measures in our production in parallel with our innovative product development. In other words, we wanted to offer architects a broad and documented sustainable product range that enables them to use Troldtekt to design healthy buildings within a flexible framework.

In the past decade, we have therefore launched a number of new C2C-certified designs. The crowning achievement in this strategy is our design series with nine characterful solutions, which were launched on the market in 2019 and which have since won a number of prizes, including a German Design Award and an ICONIC Award. Through special patterns, forms and other processing of the panels, the design solutions provide great flexibility in creating spaces with a special atmosphere – rooms in which ceiling or walls both have an acoustic regulating function and constitute a distinctive design element in the room.

It is an important point that not only individual products but the entire series of Troldtekt cement-bonded wood wool panels have achieved C2C certification. This applies to both the standard panels and the above design series. It also applies to both unpainted natural panels and panels painted in the colours white, grey and black. As from 2021, in collaboration with our paint suppliers, we also implement a new paint type that allows us to advance to the next C2C level (from Silver to Gold).

Please give information about the key objectives of your project in terms of inclusion and how these have been met

We distinguish between 1) Troldtekt users and 2) Troldtekt A/S employees.

1) A typical citizen living in Northern Europe spends up to 90 per cent of his or her time indoors. Therefore, it is crucial that our buildings are both healthy and comfortable to stay in.

Acoustic comfort is essential, as poor acoustics can cause stress and agitation. This is even more true of the large proportion of the population who have hearing disabilities and can be completely excluded from conversations in an environment with reverberating acoustics and noise. But the ‘invisible’ health of materials is also key. If we stay in rooms made of materials that are full of harmful chemicals, this may have health-damaging effects.

Our philosophy is that Troldtekt acoustic panels should be available to as wide a user group as possible. We ensure this by offering products that have a low life cycle cost relative to many other acoustic solutions. Firstly, our acoustic panels have low installation costs – simple installation with screws without subsequent filling and painting – and, secondly, they have a long life of 50-70 years without ongoing maintenance costs.

The price level and long durability mean that Troldtekt is often used in, for example, subsidised housing construction, where the developers want to choose healthy and documented sustainable solutions but have a limited budget.

2) Corporate social responsibility is one of the five criteria in C2C, and we give high priority to inclusion in our Troldtekt production too. In recent years, we have created many new jobs in one of Denmark’s fringe areas, and we attach importance to giving vulnerable citizens the opportunity to enter (or return to) the labour market. For example, several of our employees work flexible hours, and we employ a number of adult apprentices. In recent years, we have also employed deaf colleagues in our production who otherwise have difficulties finding a foothold in the labou

Please give information on the results/impacts achieved by your project in relation to the category you apply for

Wood from Danish forests and cement extracted from Danish mineral resources have been the two raw materials used in Troldtekt acoustic panels since 1935. This formula without use of harmful chemical additives helps ensure a healthy indoor climate and good acoustics.

With our C2C strategy, we have taken an already sustainable product to a new level, in which the processes behind the creation of the product also support the green transition.

Specific examples of the results are presented in the other sections of the application. The bottom line is that with our investments in innovative technology, we have succeeded in improving our energy efficiency and converting to almost 100 per cent renewable, carbon-neutral energy in our own factory, reusing waste in new cycles and transitioning to 100 per cent use of wood from sustainable forestry.

In addition, we have documented our products and processes in such a thorough and transparent way – using, for example, brand-new EPDs – that it is easy for architects and developers to choose Troldtekt when they want to design sustainable buildings that are healthy and pleasant to stay in.

Concurrently with our C2C measures, we have proven that it is possible to combine sustainability and sound economic solutions in the industry. In fact, we are experiencing that our C2C strategy has boosted our competitiveness, evidenced by us having more than doubled our business in the past decade. During this period, we have also expanded our focus to two new domestic markets, Germany and Sweden, where have established our own subsidiaries. We see an enormous potential. for transferring our values and strategic focus on sustainability to the two markets.

During our strategic work with sustainability, we have received several awards in Denmark for our C2Capproach and green transition, including the CSR Strategy Prize at the CSR Awards 2014 and the Confederation of Danish Industry’s prize DI.

Please explain the way citizens benefiting from or affected by the project and civil society have been involved in the project and what has been the impact of this involvement on the project

Strong demand for documented sustainability, especially from architects and public developers and building contributed to accelerating our decision to go all in on C2C in both product and production in the early 2010s.

Since then, we have been in continuous close dialogue with both architects and developers who represent the users of the buildings. Our consultants visit architects on a daily basis, and we hold events for architects in our showrooms, so that we also get their input on our products, product development and documentation. We attach great importance to offering the solutions for which there is a demand to support the transition towards sustainable building.

We are also involved in NGOs and networks that contribute to putting pressure on decision-makers to disseminate the C2C approach. In Germany, we support, among other organisations, Cradle to Cradle NGO, which works to disseminate a circular economy throughout society, and we are a member of Cradlenet in Sweden, which works for the same purpose.

In our three home markets, Denmark, Sweden and Germany, we are also a member of the official national industry associations that work to promote sustainable building: Green Building Council Denmark, Sweden Green Building Council and Deutsche Gesellschaft für Nachhaltiges Bauen.

In addition, we participate in forums aimed at creating healthier buildings based on the needs of citizens and society. For example, Troldtekt participates in a working group engaged in the creation of a common European materials passport, which will document the health of all materials that form part of a building. Troldtekt has also been selected to participate in a network group that will support German municipalities and constituent states in constructing sustainable buildings for educational institutions.

Please highlight the innovative character of the project

Troldtekt has been a pioneer in green transition based on the C2C principles. C2C certification was first launched in 2010, and Troldtekt was one of the first Danish companies to achieve certification – and to implement the principles as the guiding approach in its business strategy.

This means that we have not had a number of similar industrial SMEs to lean on during the process. We have had to – and still partly have to – invent solutions, solve challenges and motivate suppliers on our own to help us support the green transition.

For example, this applies to the take-back scheme for building site and demolition waste, where, after years of persistent dialogue, we are now ready to launch a pilot project with seven Danish municipalities under which wood wool waste can be collected and included in the technical cycle as a raw material in new cement. It also applies to our paints, where, after a lengthy dialogue with our paint suppliers, we can, from this year, paint our panels with new paint types with an even more sustainable footprint.

Our innovative approach also makes itself felt in the technology we use in our factory. We have invested in state-of-the-art machinery that paves the way for an environmental footprint that is as positive as possible in our processes. For example, we have invested millions of euros in high-efficiency drying ovens developed in collaboration with our suppliers and an external climate partner – and which have roughly halved our energy consumption for drying processes. We have also established a biomass boiler, enabling us to rely fully on our own supply of heat to our processes at the factory with carbon-neutral fuel.

We have also been innovative by investing massively in documentation that makes it simple for developers and consultants to use Troldtekt in their sustainable buildings – and in the development of new products (including design solutions) that make it attractive to choose a documented sustai

Please explain how the project led to results or learnings which could be transferred to other interested parties

Full transparency in our processes and results has been the keyword for Troldtekt ever since the launch of our Cradle-to-Cradle strategy. What we have done can be and is being used as inspiration for other industries both inside and outside the building trade.

For example, we give ongoing inspirational presentations of our Cradle-to-Cradle approach at seminars and webinars, and we are happy to make ourselves available if a small group wants inspiration for how to scale their sustainable initiatives. For example, in the past year, we have given presentations to local business councils, municipal council politicians and other enterprises in the building industry that find themselves in the position we were in ten years ago.

We also have a personal interest in not keeping our formula too close to our chest, but instead being open and transparent about our measures. We have invested heavily in making our production more sustainable, and the more building industry players that go down this path voluntarily, the less likely it is that we will see rigid legislation in this area.

Since 2010, we have been affiliated to the global initiatives for corporate social responsibility, the UN Global Compact, and our transparency is also reflected in our annual CSR reporting to the UN. Here we report openly and honestly on our progress – and challenges – in the Cradle-to-Cradle principles. In addition, we have just launched new EPDs, where we have openly presented all available data on the environmental footprint of our products. In this way, developers, consultants, manufacturers and competitors can see the environmental impact of Troldtekt not only in parts of the product’s life cycle but at all stages – raw materials, manufacturing, transport, use, recycling and disposal.

Is an evaluation report or any relevant independent evaluation source available?

III. UPLOAD PICTURES

IV. VALIDATION

By ticking this box, you declare that all the information provided in this form is factually correct, that the proposed project has not been proposed for the Awards more than once under the same category and that it has not been subject to any type of investigation, which could lead to a financial correction because of irregularities or fraud.

Yes